Building Information Modeling (BIM) has revolutionized how projects are designed, managed, and executed in the construction industry. BIM digitally represents a building’s functional and physical characteristics, providing valuable insights and facilitating collaboration throughout construction.

Among the many BIM software solutions (e.g., CAD, Revit, etc.) available, MSUITE BIM is a seamless plug-in that integrates with fabrication operations, streamlines construction projects, and enhances efficiency. Learn how construction firms can accelerate business objectives and how MSUITE BIM and FAB contribute to seamless integration between design and fabrication operations, improving field project outcomes.

MSUITE BIM – Revolutionizing Contractors Workflows with Design Automation

What is MSUITE BIM?

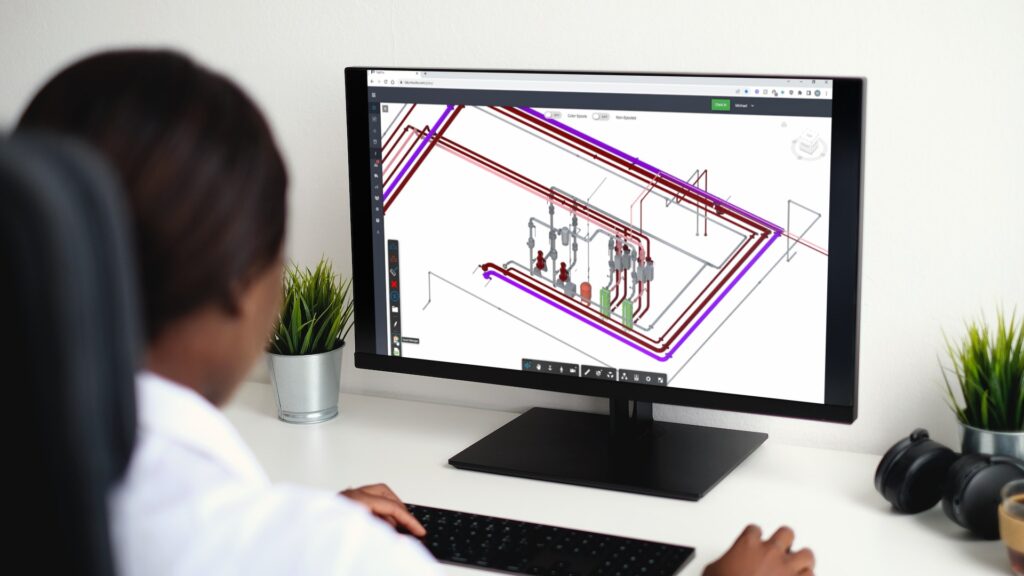

MSUITE BIM is design automation software for fast-paced mechanical, electrical, and plumbing contractors that increases design quality, eliminates the bore of dimensioning and tagging, and improves productivity up to 10x over the competition.

If you’re an MEP (Mechanical, Electrical, and Plumbing) or Industrial contractor, you know that your industry operates in a dynamic environment, often requiring quick and accurate solutions for complex projects. That’s where MSUITE BIM comes in, with its powerful suite of tools designed to automate fabrication processes, streamline hanger placement, improve point layout, and integrate BIM seamlessly into your workflow.

1. Spools and Sheets: Streamlining Fabrication

MSUITE BIM’s spooling feature is a game-changer for MEP professionals. With Auto Spool, MSUITE rapidly assembles components based on construction logic and project parameters, ensuring that what’s fabricated in the shop installs with ease in the field. This saves time and minimizes costly errors that arise during fabrication or installation.

2. Do it Yourself (DIY) Spool Sheets: Automating Detailing

Detailing is a crucial part of the MEP process. MSUITE BIM’s DIY Spool Sheets feature automates the placement of views, dimensions, tags, and more. Whether you need dimensions on 3D views or want to automate Weld Mapping, MSUITE BIM can handle it, reducing the need for manual work and potential human error.

3. Hangers and Supports: Effortless Placement and Reporting

Hanger placement can be tedious, but MSUITE BIM simplifies it by empowering design teams to place hangers efficiently throughout the model. This not only saves time but also ensures hangers are correctly positioned. Moreover, automating point placement and reporting for layout teams in the field streamlines communication and enhances collaboration.

4. Integrating BIM to Fabrication: A Seamless Transition

Seamless integration with existing systems is crucial for MEP professionals. MSUITE BIM makes it easy to push and pull data to and from Autodesk BIM360 Docs and Forge in 2D and 3D formats. Additionally, you can connect model information directly to the cut tables, ensuring that fabrication processes remain synchronized with the BIM model.

5. MSUITE BIM in Action

Real-world testimonials speak volumes about the impact of MSUITE BIM. For example, Brandt, a company delivering designs and Fabrication to commercial and industrial facilities in Texas, has found MSUITE BIM to be a crucial component in achieving superior designs and accurate fabrication.

Key Product Features

-

Autodesk Revit Plug-in: MSUITE BIM integrates seamlessly with Autodesk Revit, providing a user-friendly ribbon containing tools to expedite spool and sheet creation.

-

Auto-Spooling: Automatically identify spools based on a set of rules, making the process more efficient and less prone to errors.

-

Create & Color Spools: Manual creation of spools is made easy, and you can color-code them for quick identification.

-

Break Spools: Adjust existing spools quickly or create new ones.

-

Title Block & Sheet Layout: Customizable Title Block support with parameter mapping and easy schedule creation and placement.

-

Speed: MSUITE BIM’s automation features can save an enormous amount of time compared to manual processes. For example, one client gained 5.5x productivity in spooling.

-

Auto-Dimensions: MSUITE BIM automatically dimensions rolling offsets and displays them in various views.

-

Auto-Tag: Automatically tag and annotate components, reducing the need for manual annotation.

-

Model Viewer: Cloud model uploads allow the shop floor to view 2D PDFs, spool maps, and 3D models, promoting better collaboration and understanding.

-

Updates: MSUITE BIM frequently releases updates based on customer feedback, ensuring the tool remains practical and up to date.

How can MSUITE help your construction firm materialize key business objectives?

- Continuous Growth and Development: Harness the expertise of MSUITE’s development team, known for its excellence, and benefit from the constant rollout of new software features. These features are instrumental in helping contractors scale and expand while ensuring complete alignment between estimating, engineering, and VDC functions.

- Seamless Transition to Revit: Ensure a smooth transition into the Revit® environment and emphasize alignment and software readiness across our Engineering, VDC, and fabrication departments. Embracing the Revit® platform is the most fitting solution to facilitate your transition.

- Enhance Spooling Efficiency: Boost the current spooling process’s productivity and rectify issues stemming from the use of AutoCAD® with the Fabrication of ITM files. If you’re producing spools daily, addressing software inefficiencies and limitations necessitates a new solution to increase production.

- Future-Proof Spooling: Develop a forward-looking spooling process that can accommodate your growing backlog. As the industry shifts towards Revit®, there’s an immediate opportunity for Fabrication. Leveraging Revit® allows firms to manage backlog effectively and seamlessly generate .maj files for Fabrication.

- Integration with ERP Systems: Recognize the significance of integrating with fabrication ERP systems and machines on the shop floor. Many companies have invested substantially in their custom-built ERP systems and hardware on the floor. MSUITE BIM and MSUITE FAB shop management seamlessly integrate with these types of software and hardware to elevate fabrication shop operations.

- Integrate MSUITE BIM and Fab to Machines: MSUITE is designed to integrate with machines on the shop floor, providing a streamlined and efficient workflow for BIM-to-fabrication-to-field processes. This integration involves various elements to ensure seamless tracking of projects, communication, and data exchange between the software and the machines to improve productivity, increase visibility, and reduce costs.

MSUITE’s software flexibility and ability to integrate with various machines offer both short-term and long-term scalability and expansion potential.

MSUITE is a powerful solution that has the potential to revolutionize the workflows of MEP professionals. With features like automated spooling, seamless integration with existing systems, and real-time collaboration, this software allows MEP professionals to work more efficiently, reduce errors, and save valuable time. Its adoption by industry leaders like Brandt highlights its effectiveness in enhancing designs and fabrication processes.

If you’re in the fabrication industry, MSUITE is a tool worth considering to optimize your processes and stay competitive in a fast-paced industry.