Overview

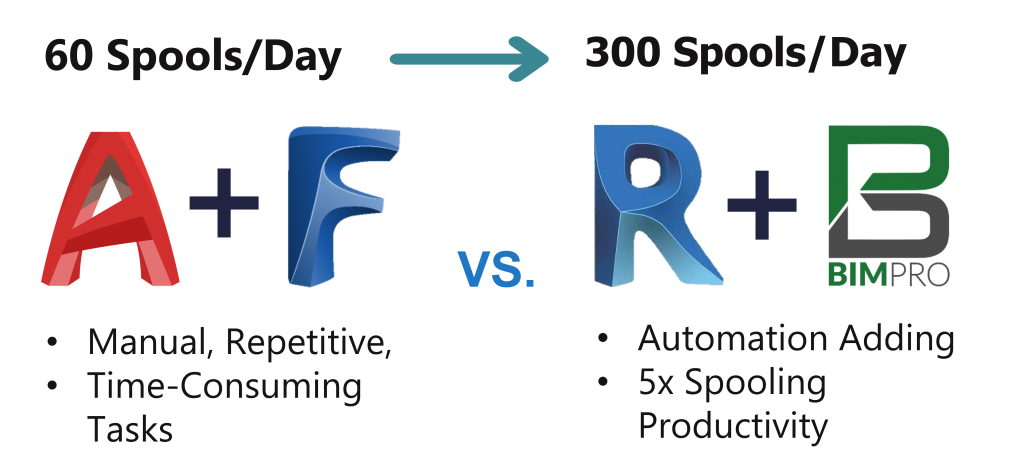

In Texas, Brandt, an MCAA member contractor, utilizes MSUITE BIM’s spooling functionality in Revit® to increase their capabilities 5-fold. Designing in Fabrication CADmep® and spooling in Revit, Brandt’s unique workflow allows them to transition their design and detailing teams into Revit® at their own pace while leveraging MSUITE BIM’s easy-to-use platform to increase their speed and accuracy.

“As a result, Brandt has been able to go from spooling 60 sheets per person per day in CADmep® to over 300 using MSUITE BIM and Revit®, achieving a five times increase in productivity,” said JT, Director of VDC Technologies at the Brandt Companies.

MSUITE BIM’s Automatic Spooling offers over 5.5x productivity gain.

John “JT” Trammell

Director of VDC Technologies | Brandt Companies

About Brandt

Established in 1952, Brandt is one of the largest MEP service providers in mid America and serves several industries Corporate Campus, Healthcare, Hospitality, Government, Education and several others. They have a large in-house staff of 30 engineers, 65 MEP VDC modelers across six locations in Austin, Dallas, Houston, and San Antonio, Texas. Revenue in 2020 was around 500 million with approximately 2000 employees. Most importantly, they have a .70 CR safety rating for mechanical contracting.

In 2019, Brandt leadership came to JT with a concise list of business goals for the company to achieve. These initiatives also became requirements for any solution provider that Brandt was going to partner with in the future.

“I said to Britton Langdon, CEO of MSUITE, the number one priority on our list of business needs is successfully integrating with our ERP BOWS system.

After working closely with MSUITE’s amazing implementation team, we were sold. The MSUITE team delivered superior software, training and support to ensure customer success, said JT, Director of VDC Technologies at Brandt Companies.

Brandt’s Business Needs

Brandt had six business initiatives that meant requirements for MSUITE to meet before forming the partnership.

- Increase our productivity of the current spooling process and address the current swelling process by using AutoCAD® with fabrication ITM files. Brandt’s staff were pushing out on average 60 spools a day primarily because of software inefficiencies and limitations, so a new solution was necessary!

- Develop a future spooling process to incorporate our backlog. The industry is continuing to move to Revit®, so the opportunity was immediate for fabrication. “We knew Revit® not only allowed us to handle our backlog, but we can .maj out of fabrication, said JT.

- Transition seamlessly into Revit to focus on alignment and software readiness between Engineering, VDC, and fabrication. The Revit® platform was the right solution to help Brandt with its transition.

- Integrate with Brandt’s fabrication BOWS ERP system. Brandt invested heavily for a decade in their custom-built Mechanical Contractor ERP system, so any solution implemented must integrate seamlessly with their BOWS system.

- Continuous scalability and development. “MSUITE’s dev team is second to none and continuously roll out new features in the software that helps Brandt scale and grow to as well as complete the full alignment between estimating engineering and VDC,“ said JT.

- Opportunities for future partnerships were another reason Brandt selected MSUITE. The flexibility of MSUITE’s software and ability to integrate with several machines offers short and long-term scale and expansion.

Brandt Study Highlights Improvements

Comparison study confirms findings

“In general, Autodesk® to fabrication forces manual, repetitive, time-consuming tasks that are productivity killers, so reversing those tasks and comparing to the automation from Revit® to MSUITE is how they were able to gain five times of productivity,” said JT. The productivity improvement points included: Defining Spools, Creating Spool Sheets, Dimensioning Spool Sheets, Tagging Spool Sheets, Generating Spool Maps, and Integrating with Shop Equipment.

Defining Spools

Revit + MSUITE – Automated, and everything is connected and ordered. MSUITE’s plug into Revit® provides point and click automation, letting the program work for users.

Settings allow you to dictate naming conventions, length of the spools, how many offsets you want, such as valves, automatic breaks at flanges, and much more. The time-saving results are staggering:

MSUITE BIM Automatic Spooling option offers over 5.5x productivity gain.

- + Automatically defined spools in 16 seconds.

- + 42 seconds faster than manual Revit® Spooling.

- + 1 minute 14 seconds faster than CAD Spooling.

Creating Spool Sheets

Revit + MSUITE – Automated, creating multiple sheets at one time allows you the flexibility of viewing your work and storing files within one file.

One basic template saves users 30 seconds and builds over larger jobs.

Spend Less Time Detailing – DIY Spool Sheets easily automates the placement of views, dimensions, tags, and more. Schedules, naming by assembly name, and creating views.

Dimensioning Spool Sheets

Revit + MSUITE – Automated, and everything is connected and ordered. MSUITE’s plug into Revit provides point and click automation, letting the program work for users.

+ 3:11 minutes saving per spool sheet. 3x Productivity for dimensioning spool sheets.

Tagging Spool Sheets

Revit + MSUITE – Automatically tag spool sheets.

+ 19 second saving per tagging spool sheets.

Generating Spool Maps – Brandt uses sheet files to generate spool maps.

Revit + MSUITE – Allows users to select which services they want to display and isolate them.

For example, users can be selective in displaying cold water vs. hot water distribution pipes or other components and easily isolates them. In addition, users can select view templates that are set up for their architectural grid lines.

+ 2:67 minutes saving per spool map. 2.5x Productivity.

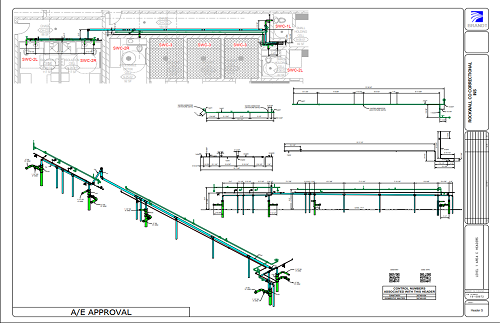

Completed Spools

Revit + MSUITE – The completed spool sheet contains several different views, and all of it was automatically performed in Revit® and MSUITE.

“The Bill of Materials, Cut List, and Joint Tracking are all schedules brought in and performed in minutes rather than tens of minutes using CAD.”

James Young

Spooling Manager/Virtual Designer

Brandt Companies

Integrating with Shop Equipment

Recently, Brandt integrated MSUITE Fab tracking solution with the shop’s Watt pipe cutting machine, demonstrating significant time and material savings.

“By getting the machine to recognize you’re ITMs and pipe cut automatically pays dividends, and we use 3DP software. I was talking to the fabrication shop manager, and he said instantly we saved 30 to 35%. If you go from cutting, marking, looking at angles on pipes to automatically cutting with the machine, you are instantly going to find labor and material savings,” said JT.

The Digital Fabrication Shop

“MSUITE FAB’s flexibility supports many different workflows with Watt and other machines but getting it to support all of those different types of hole cuts are either out-of-the-box items or custom-made saddles or fish mouth. The flexibility is impressive,” said JT.

Making the Transition

MSUITE’s flexible technology enabled Brandt’s team to transition mid-project and for new projects. The transition fears drifted away in just under a month for current staff. “Once we integrated MSUITE with our fabrication ERP, BOWS, it allowed us the flexibility to take an .MAJ out of the current project that was happening in fabrication and try it with MSUITE BIM,” said JT.

MSUITE BIM Automatic Spooling feature offers over 5.5x productivity gain.

MSUITE BIM Automatic Spooling feature offers over 5.5x productivity gain.

“Brandt has been able to go from spooling 60 sheets per person per day in CADmep® to over 300 using MSUITE and Revit®, achieving a five times increase in productivity.”

JT, Director of VDC Technologies

Brandt Companies

MSUITE BIM Automatic Spooling feature offers over 5.5x productivity gain.

MSUITE BIM Automatic Spooling feature offers over 5.5x productivity gain.