Automate VDC modeling, streamline detailing, and move your model to fabrication faster than ever.

VDC and prefabrication teams face intense pressure to deliver more work in less time. The firms leading the industry are those that streamline design-to-fabrication execution, automate modeling, and eliminate bottlenecks from their workflows.

Contractors can no longer rely on manual Revit modeling or disconnected communication between design, fabrication, and field. The goal is simple: automate repetitive modeling tasks, connect BIM data to fabrication, and eliminate bottlenecks that slow throughput.

Below are ten proven strategies used by leading MEP and industrial fabricators to accelerate VDC output, reduce rework, and deliver projects faster, while maintaining quality and profitability.

1. Automate Repetitive Modeling Tasks in Revit

VDC teams spend up to 25% of their modeling time repeating low-value tasks such as hanger placement, sleeve insertion, or parameter setup. Automating these functions with solutions like MSUITE BIM enables teams to generate, tag, and manage hundreds of elements with precision—in minutes rather than hours.

Automation tools can:

- Apply parameters and shared data across entire systems.

- Eliminate manual tagging errors.

- Enable rapid updates across linked models.

This allows designers to focus on constructability and coordination instead of repetitive detailing.

2. Standardize Your Modeling Templates and Families

Inconsistent families and templates are one of the biggest drags on VDC speed. Standardization ensures modelers can start faster, maintain uniform geometry, and export directly to fabrication with fewer edits.

Create company-wide Revit family libraries that align with your fabrication standards and naming conventions. Then use those templates across all projects to streamline QA/QC and export workflows.

MSUITE BIM automatically enforces these standards, improving quality while saving hours on every project.

3. Use Cloud-Based BIM Collaboration

Stop wasting time with local saves or file version conflicts. Cloud collaboration platforms allow multiple users to work simultaneously on the same model in real time, reducing idle time and coordination lag.

Connected solutions—like Autodesk Construction Cloud integrated with MSUITE—ensure that VDC, fabrication, and field teams have access to the latest version of the model. This eliminates guesswork and speeds up coordination meetings by keeping everyone aligned on the same data source.

4. Leverage Rule-Based Automation for Hanger Placement

Manual hanger placement is one of the most time-consuming parts of modeling. Automating it can improve throughput dramatically.

With MSUITE Hangers, contractors can define rules for spacing, material, and load requirements—then automatically populate the entire system.

Paired with DEWALT Toughwire, installers can move from model to field installation up to 3X faster than traditional methods. The result is a seamless BIM-to-FAB-to-FIELD workflow that shortens schedules and simplifies coordination.

5. Connect Your Model Directly to Fabrication

Moving models from Revit to fabrication software or cutting equipment often creates delays. With MSUITE FAB, models can move directly from VDC to fabrication with automated spool generation, weight tracking, and production scheduling.

By connecting your BIM and shop environments:

- Spools are created automatically from predefined rules.

- Material lists, weights, and quantities are exported instantly.

- Production teams gain clear visibility into workload and deadlines.

This direct connection removes the “translation gap” between design intent and shop reality—saving hours per week and reducing fabrication errors.

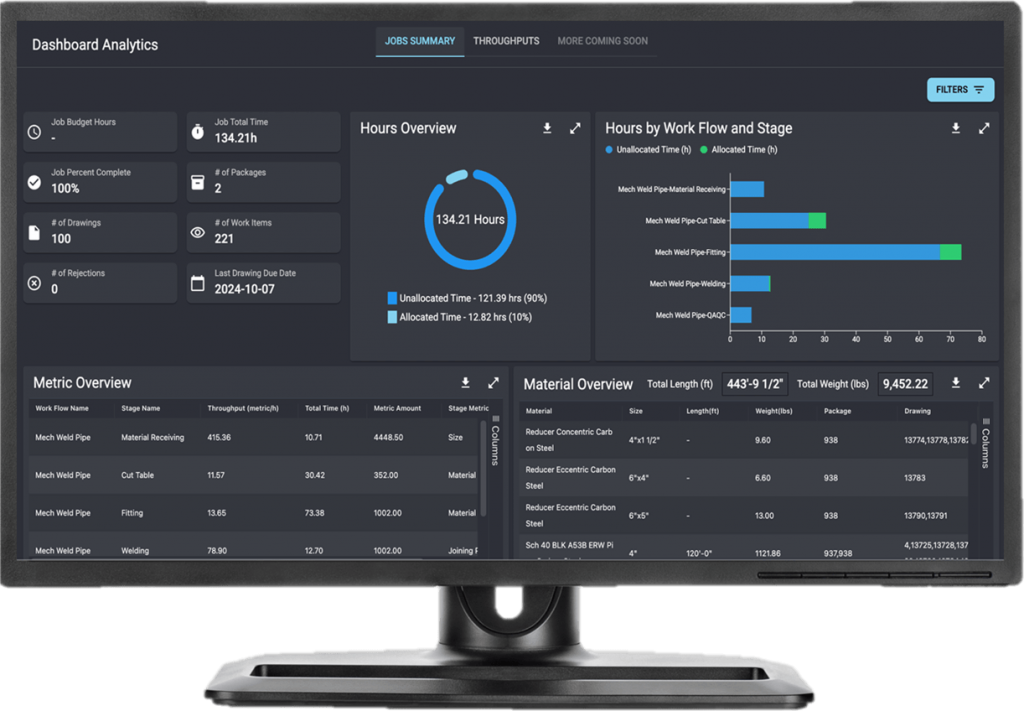

6. Monitor Throughput with Real-Time Analytics

What gets measured gets improved. Tracking fabrication throughput helps identify bottlenecks before they impact delivery.

MSUITE Analytics provides real-time dashboards showing output by station, trade, and spool. Managers can see labor hours, material usage, and rework percentages across the entire shop.

Contractors using MSUITE report:

- 25% increase in throughput within the first six months.

- 50% faster reporting cycles using automated dashboards.

These insights enable proactive decisions that keep production aligned with field installation schedules.

As the construction industry moves toward 2026, prefabrication and VDC workflows are set for significant expansion. According to Future Market Insights, the global modular and prefabricated construction market is projected to reach nearly US $183 billion by 2026, up from US $173 billion in 2025. This increase reflects contractors’ embrace of offsite fabrication to meet tighter schedules and overcome labor shortages.

Reports from OConstruction and The Birm Group note that modular and offsite methods are shifting from niche to mainstream, with MEP assemblies and prefabricated racks driving most of the adoption. In this environment, VDC leaders who automate Revit modeling, integrate fabrication workflows, and connect teams across the project lifecycle will be positioned to deliver faster, safer, and more profitable projects.

7. Integrate Design and Fabrication Teams Early

The earlier fabrication teams participate in the VDC process, the faster your project moves downstream. Early collaboration ensures constructability, reduces redesigns, and enables prefabrication to start sooner.

Establish Design for Manufacture and Assembly (DfMA) principles:

- Engage fabrication leads during model coordination.

- Validate that modeled systems meet shop standards.

- Align hanger spacing, joint types, and spool limits upfront.

MSUITE’s connected workflow bridges design, fabrication, and installation teams on a single platform, enabling concurrent progress rather than sequential hand-offs.

8. Eliminate Manual Spooling and Tagging

Manual spooling consumes hours of tedious work. Automated spooling tools allow you to select systems or zones and instantly generate fabrication-Ready packages.

With MSUITE BIM’s spooling automation, spools are organized by service, zone, or installation sequence. Tags and parameters are automatically applied. PDFs, MAJ files, and fabrication drawings are exported in a single step. This process not only accelerates production but also reduces errors and minimizes manual entry.

9. Enable Continuous Field Feedback Loops

The fastest prefab shops close the loop between field performance and design. Capturing as-built data, field status, and installation progress allows BIM teams to adjust models and improve future efficiency.

With MSUITE Field View, crews can:

- Access spool drawings and delivery updates directly on tablets.

- Log installation progress, photos, and markups.

- Send updates back to BIM automatically.

This feedback accelerates VDC learning cycles, enabling faster modeling and more thoughtful planning for every new project.

10. Train and Upskill VDC Teams in Automation

Technology only works as fast as the people behind it. Investing in Revit automation training, data management, and workflow optimization creates a culture of speed and precision.

Encourage VDC staff to:

- Learn Dynamo scripts and Revit API basics for custom automation.

- Explore add-ins that eliminate repetitive clicks.

- Participate in vendor-led workshops from MSUITE or Autodesk to master connected workflows.

Upskilled teams leverage technology to do in hours what once took days—unlocking compounding gains across every project phase.

Benchmark and Improve Every Project

Tracking the time required to model, fabricate, and install, by linear foot or system type, is one of the simplest ways to identify performance gaps. The best contractors treat each project as an opportunity to learn and improve the next.

Firms using MSUITE consistently report measurable gains, including a 5X increase in spool creation productivity, a 40 percent increase in fabrication throughput, and a marked drop in rework. These improvements come from real-time visibility, connected data, and automation across the BIM-to-FAB workflow.

According to a McKinsey Global Institute report, construction productivity could grow by 50 to 60 percent through digitization and process integration. Benchmarking your VDC and prefabrication performance puts that opportunity into action, helping teams deliver more with the same labor and resources.

Accelerate from Model to Market

In an era where owners demand faster delivery, MEP contractors need every efficiency advantage. By combining automation, connected workflows, and real-time insights, VDC and prefab teams can move from modeling to fabrication to installation without friction.

MSUITE’s management suite—BIM, FAB, and Hangers empowers teams to accelerate throughput while maintaining control, quality, and profitability.

Ready to Accelerate Your VDC and Prefab Operations?

Schedule a conversation with an MSUITE expert today to see how leading contractors are automating Revit modeling, increasing fabrication throughput, and delivering projects on time, even with condensed schedules.