The 2026 MEP Innovation Conference is set to make one reality clear: MEP contractors are no longer debating whether to modernize. They are deciding how fast they can scale proven workflows without breaking margins, burning out teams, or losing control of quality. Across sessions, panels, and conversations on the show floor, the focus is shifting toward systems that deliver repeatable results across BIM, fabrication, and the field. The contractors pulling ahead are not chasing tools. They are building connected operating models.

That direction aligns directly with how MSUITE and DEWALT Construction Technology are showing up at the conference, by unifying workflows, standardizing execution, and helping contractors scale fabrication-driven delivery with confidence.

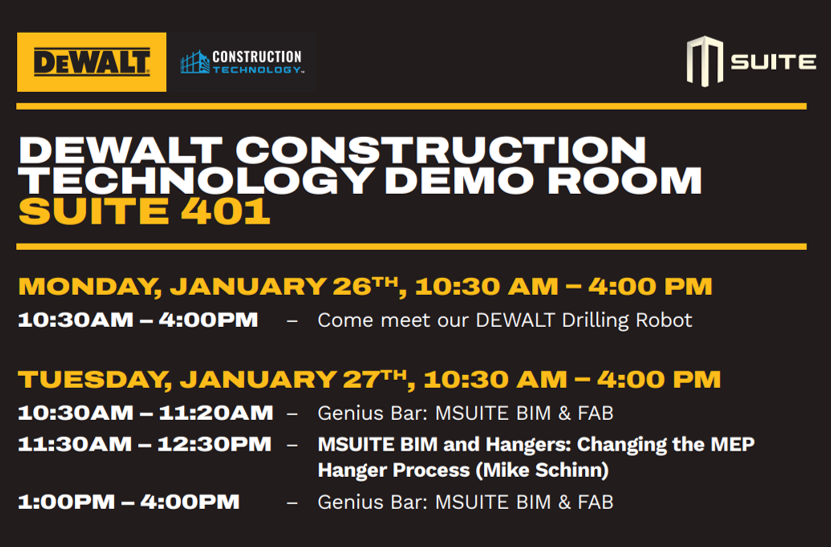

Attendees can see this approach firsthand at our Booth 102 during exhibit hours AND our Demo Room 401, where MSUITE experts will walk through real production workflows and answer contractor-specific questions.

The New Growth Constraint: Fragmentation, Not Demand

As the MEP Innovation Conference approaches on January 26–28, 2026, one reality is already clear: most high-performing MEP firms are not short on backlog. They are constrained by fragmentation.

That fragmentation shows up everywhere:

-

BIM models that stop at coordination

-

Fabrication information disconnected from production reality

-

Field teams installing from outdated or incomplete deliverables

-

Leaders managing with lagging reports instead of real-time insight

This is the challenge contractors are coming to the conference to solve. As firms scale, every disconnect between BIM, fabrication, and field execution becomes more expensive. Growth does not fail because of demand. It stalls because workflows break under pressure.

The firms pulling ahead are addressing this by establishing a single, fabrication-centered source of truth that drives decisions from model through install—an approach MSUITE will demonstrate live in Demo Room 401.

Fabrication Is the Control Point for Scale

One of the clearest themes shaping the conversation going into the conference is the elevation of fabrication from a support function to a strategic control point.

Fabrication-centric contractors are winning because they can:

-

Lock constructability earlier in BIM

-

Standardize spooling and hanger placement

-

Balance shop capacity against field demand

-

Reduce rework before material ever ships

This is where MSUITE stands apart. Instead of treating fabrication as a downstream output, MSUITE structures BIM, spooling, production tracking, and installation data into one connected system.

The outcome is predictable throughput, controlled scaling, and fewer surprises—replacing reactive firefighting with disciplined execution as contractors head into 2026. These workflows will be showcased and discussed in depth in Demo Room 401.

See MSUITE in Action – Demo Room 401

As MSUITE heads into the conference under the DEWALT Construction Technology umbrella, several product areas directly reflect the themes contractors are discussing on stage—and will be demonstrated live in Demo Room 401.

MSUITE BIM

Modern BIM is no longer just about coordination. MSUITE BIM enables fabrication-ready modeling that drives spools, hangers, and material planning downstream without rework. Contractors model once and execute many times.

MSUITE FAB

Fabrication leaders consistently emphasize visibility. MSUITE FAB delivers real-time insight into spool status, labor progress, and bottlenecks across the shop, allowing teams to scale volume without sacrificing schedule certainty.

MSUITE Hangers

Hanger placement continues to surface as a hidden productivity drain. Manual hanger detailing slows modeling and introduces field variability. MSUITE Hangers automates support system layout directly from BIM, standardizing installs and reducing labor exposure.

Analytics and Production Intelligence

Contractors need answers, not assumptions. MSUITE Analytics connects BIM and fabrication data into dashboards that show what is on track, what is slipping, and where teams need to intervene before problems hit the field.

All of these capabilities come together in Demo Room 401 through guided demos and personalized walkthroughs.

Why DEWALT Construction Technology Leads the Way

Trust is expected to be a recurring theme throughout the conference. As contractors scale, they gravitate toward platforms backed by brands that understand jobsite reality and long-term execution.

DEWALT Construction Technology brings a century-long legacy of performance-driven tools into the digital layer of construction. That matters to MEP firms making enterprise decisions around standardization, security, and platform longevity.

Together, DEWALT Construction Technology and MSUITE give contractors confidence that their digital foundation can scale with the business instead of becoming another system to replace—a message reinforced in Demo Room 401.

From Innovation to Execution Discipline

A consistent message expected to emerge across conference sessions is that innovation will only matter when it shows up in daily execution.

As the industry looks ahead to 2026, high-growth contractors are expected to describe the same operating principles:

-

Standardize workflows before adding volume

-

Push decisions upstream into BIM and fabrication

-

Measure production in real time rather than after the fact

-

Treat structured information as an operational asset

MSUITE is built around these principles. By structuring fabrication operations across BIM, shop, and field, MSUITE helps contractors move beyond heroic project management toward disciplined, scalable delivery—an approach explored in detail during live demos in Demo Room 401.

This structure also creates the foundation contractors need to adopt advanced analytics and AI-driven insight as their operations continue to mature.

What Contractors Will Take Away from the Conference

The 2026 MEP Innovation Conference reinforces a simple truth: growth rewards clarity.

The firms that win in the next cycle are not the ones with the most tools. They are the ones with the cleanest, most connected workflows.

For contractors attending the conference, MSUITE and DEWALT Construction Technology present a clear path forward:

-

Fabrication-driven BIM instead of model handoffs

-

Real-time production visibility instead of status meetings

-

Automated hanger and spool workflows instead of manual workarounds

-

One system of record instead of disconnected point solutions

Get Personalized Demos in Demo Room 401

If you are attending the MEP Innovation Conference 2026, visit Demo Room 401 for a guided MSUITE session and / or personalized demonstration tailored to your workflows and project needs.

Demo Room Session Details

Session Title: MSUITE BIM: Next-Level MEP Hanger Modeling & Automation

Session Description: Discover how MSUITE BIM and MSUITE Hangers help teams model and fabricate hangers with greater speed and accuracy. Learn how reactive hangers that adapt to design changes, simultaneous modeling alongside MEP systems, and automated field point and beam detection can simplify workflows and reduce errors. This session includes live demonstrations and practical takeaways to help teams deliver projects faster and more efficiently.

Intended Audience: VDC, BIM, Detailers, Operations, Fabrication Managers

Date/Time: Jan 27 / 11:30 AM – 12:30 PM

The future of MEP growth is not experimental. It is structured, connected, and fabrication-first. Start in Demo Room 401.