Background & Project Overview

Exceptional teamwork, technology, and advanced planning helped the owner save $5.6M and potentially generate $60M in indirect operational revenue.

Headquartered in Pittsburgh, PA., Limbach is a nationwide company with 1500 employees, and 10 major branches across the United States. As a leading MEP contractor, Limbach leverages MSUITE to offer integrated building systems solutions with expertise in design, fabrication, installation, management, service, and maintenance of HVAC, mechanical, electrical, plumbing, and control systems. The firm includes an in-house MEP+C design build staff and 8 fabrication shops with a total fabrication capacity of about 208 thousand square feet. Additional fabrication shop capacity is frequently acquired as needed.

| Project & Shop Statistics | Highlights |

|---|---|

| MSUITE for BIM to Fab | MSUITE BIM and Fab used to take model information to the shop floor and track real-time status and productivity. |

| Budget: $450M | 220 Racks (4400 lf Total Footage) of multi-trade systems - Six at a time: 71,500 Linear Feet of all services fabricated. Twenty-four racks worked on simultaneously. Six delivered every 4 days. |

| Shop 25,000 SF | 3-Weeks to start, build, ship and install each assembly line (6 racks). |

| Shop Manpower | 14 People who Tested, Insulated, and valve tagged before delivery. |

| 8,000 Hours for M&P | Increased productivity and quality due to environmental control and streamlining. |

| Insurance Advantages | MSUITE was used for detailed tracking required for insurance and supported billing. |

| Top-down stakeholder collaboration | Heavy Investigation on “Best Fit” Fabrication Opportunities. |

| Multi-Trade Prefabrication | Field Install Time: 220 Hours Resulting in 2-Months Schedule Savings and 30% reduction in on site manpower. |

The McLaren Greater Lansing Hospital offered Limbach and its broad group of stakeholders the opportunity to plan and leverage prefabrication to achieve incredible results. The project was led by savvy ownership with substantial experience and familiarity with modular construction.

From the beginning, the joint venture Barton Malow-Christman and its stakeholders were on board with Limbach delivering the mechanical, electrical, plumbing, and fire protection aspects of the project. The group (which included the owner, engineer, general contractor, and subcontractors) invested heavily in design-for-manufacturing (DfMA) principles to engineer the building for prefabrication.

Technology for Multi-trade Assemblies

Technology for Multi-Trade Assemblies

Limbach contacted MSUITE, to discuss how their software can outfit the pop-up Fab Shop for multi-trade contractor use and mitigate risk for the team. In addition, the MSUITE team was leveraged to layout the shop workflows.

Limbach already uses MSUITE at its fabrication facilities across the U.S., but multi-trade usage was a new opportunity. MSUITE’s software is an innovative solution for managing productivity for Fab Shops. The cloud-based platform offers production tracking, reporting, and documents everything from start to install for multiple trades. “MSUITE’s expertise in fabrication helped Limbach come up with the fab shop layout for optimal flow.

Limbach’s team set up 220 total racks and six assembly lines to add 4,400 linear feet of racks with a total of 71,500 linear feet of conduit, piping, plumbing, sheet metal, cable tray, and drywall. All of these were tested, inspected, and insulated in place. The total assembly time in the shop for Limbach’s scope of work was 8,000 hours for a four-day turnaround per line. The entire process per floor was approximately a three-week turnaround, which included the shop assembly line, delivery, installation, and finalization. The environmental control and ability to streamline the work increased productivity and quality.

What was Fabricated

Utilizing Lean and Design for Manufacturing concepts such as “Choosing by Advantage”

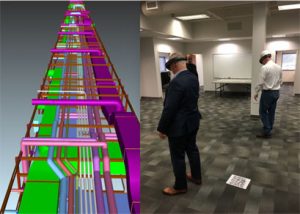

The Project team was creative in investigating high-value targets for prefabrication. The DfMA process helped the team visualize racks and corridors to reassure the owner of the strategy to meet the building’s life cycle needs and aggressive schedule. By utilizing Mixed Reality, the owner’s representatives were able to explore the racked systems to simulate the ease of installation and future maintenance.

The DfMA process meant utilizing Lean manufacturing concepts such as identifying high-value fabrication “Targets” like Headwalls, Wet walls, Bathroom pods, and more. The team employed the “Choosing by Advantages” technique to select the right modules for the project. Key decision-making factors included the availability and costs of shop space, job site congestion, material handling, and delivery.

Mixed Reality was also used to QAQC modules and allow the owner to “walk through” virtual racks along side the fabricated racks.

Finding the Fab Facility

After the project team settled on the design and prefabricated targets, there was not much space available for fabrication on site.

They were fortunate, however, and acquired the Pine Tree Shop, a 25,000 square foot warehouse, to convert into the fabrication facility they needed. It was a huge advantage to quickly set up, manufacture, and transport materials to the job site, which was only 2 miles away.

Additional Pre-Fab Benefits

- — Shop Testing, Insulation and Tagging

- — Michigan winter weather mitigated

- — Enhanced Shop Safety Conditions

- — COVID: lower numbers of jobsite workers and shop employees separated by workstations

- — Increased productivity

- — Increased quality

- — Reduced overall schedule

- — Reduce costs

Collaboration Saves Time, Labor

Collaboration across trade partners benefits all.

The McLaren Greater Lansing Hospital project experienced considerable collaboration across all trade partners on the jobsite. The manpower in the shop included just 14 people for all trades, resulting in a 30% reduction in trade labor on-site for install of the racked systems. Installing the racked systems in the building took about an hour per rack, totaling 220 hours.

The assembly on the jobsite was extraordinarily efficient compared with stick-building and eliminating the extra time onsite produced significant savings. MSUITE helped onsite and fabrication teams alike track the real-time status and productivity metrics.

“The 2-months schedule savings resulted in a $5.6 million-dollar direct return to the owner. Two months of unexpected operational time for the health care facility can mean an indirect revenue impact of $60M.

Mark Lamberson CPD

National VDC Manager| Limbach

McLaren Greater Lansing Hospital Project

Limbach offered the following lessons learned from the McLaren Greater Lansing Hospital Project:

- — Early involvement: Early team involvement is critical to success.

- — Building the team: All stakeholders must be present (carpenters, etc.).

- — Fabrication support: Prefabrication must be supported from the top down.

- — Mindset shift: The team must adopt the attitude of “What can’t we fabricate?”

- — Fabrication shop proximity to jobsite: Consider over-the-road requirements, permits, etc.

- — Team decisions: Use the entire team for decisions; different stakeholders will perceive different benefits and drawbacks.