Bassett Mechanical Powers The Future of Fabrication

A DEWALT® CASE STUDY

COMPANY: Bassett Mechanical

INDUSTRY: Industrial Refrigeration, HVAC, Plumbing, Building Automation & Controls, Metal Fabricating, and Service Solutions

LOCATIONS: Wisconsin and Minnesota

KEY CONTACT: Tyler Peterson, VP of Manufacturing

“MSUITE has completely changed the manufacturing game for us. “By digitizing our workflows and automating key processes, we’ve achieved levels of efficiency and accuracy that were previously unimaginable. It’s a transformative tool that has truly elevated our operations.”

TYLER PETERSON

VP of Manufacturing, Bassett Mechanical

Overview

Bassett Mechanical, a leading provider of custom-built industrial refrigeration, HVAC, plumbing, metal fabrications, and service solutions, has a long-standing commitment to innovation and quality.

To further advance their fabrication processes, Bassett adopted MSUITE’s FAB and BIM software, positioning themselves at the forefront of technological innovation in the construction industry.

CHALLENGES BEFORE ROLLING OUT MSUITE: MORE COMPLEX FABRICATION

As fabrication demands grew more complex, Bassett Mechanical needed a solution to increase shop efficiency, reduce errors, and provide real-time visibility into their fabrication workflows. Their goal was to streamline operations from design through production, ensuring projects stayed on schedule and within budget while maintaining their high-quality standards.

THE SOLUTION: MSUITE BIM AND FAB

Enabled seamless coordination between design and fabrication, enhancing Bassett Mechanical’s ability to deliver precise, constructible models directly to the shop floor.

Streamlined shop management, providing a centralized platform for tracking production progress, material status, and labor productivity involved with fabrication and throughput.

“By going digital with MSUITE FAB, we’ve reduced the manual processes of administering work—less printing, copying, scanning, and moving documents around the shop. We now have real-time visibility into project status, welder IDs, and heat numbers.”

TYLER PETERSON

VP of Manufacturing

Bassett Mechanical

MSUITE IMPACT ON PRODUCTION

Since implementing MSUITE, Bassett Mechanical has seen dramatic gains in production output. By automating previously manual processes and delivering real-time data to the shop floor, the team can focus more on building and less on administrative coordination. These improvements have allowed Bassett to take on more complex projects with confidence, knowing they have the

tools to deliver on time and at a higher level of quality

KEY RESULTS & IMPACT

By adopting MSUITE’s connected BIM and FAB solutions, Bassett Mechanical achieved measurable gains across their operation. From improved communication to advanced automation, these results showcase the power of integrating technology into every stage of fabrication.

-

— STREAMLINED COMMUNICATION

-

— REDUCED BOTTLENECKS

-

— DIGITAL DOCUMENTS & WORFLOWS

-

— AUTOMATED FABRICATION TOOLS

-

— SOFTWARE SYNERGY (BIM, FAB, TOOLS)

-

— ENHANCED TRACEABILITY

FROM MANUAL TO MODERN

Transitioning from manual workflows to MSUITE’s modern digital platform has been a game-changer for Bassett. Tasks that once required extensive paperwork, duplicate data entry, and manual tracking are now handled efficiently in real-time. This shift has streamlined communication between teams, reduced bottlenecks, and allowed for a more proactive approach to managing shop operations.

DIGITAL EVERYTHING

From drawings and schedules to timecards and QC documentation, the entire workflow is now digital, reducing errors and increasing efficiency.

AUTOMATED FABRICATION TOOLS

The CNC Angle Clipper, CNC Structural Profiler, CNC Pipe Profiler, and back gauge on Marvel saw—integrated with cutting software such as Procam and PypeServer—allow for direct export of cutting files from design files, automating cutting, punching, and layout tasks that were once programmed manually.

“MSUITE FAB has allowed us to get all our projects into one system, giving us the ability to track performance and analyze throughput by drawing, package, and workflow.”

TYLER PETERSON

VP of Manufacturing

Bassett Mechanical

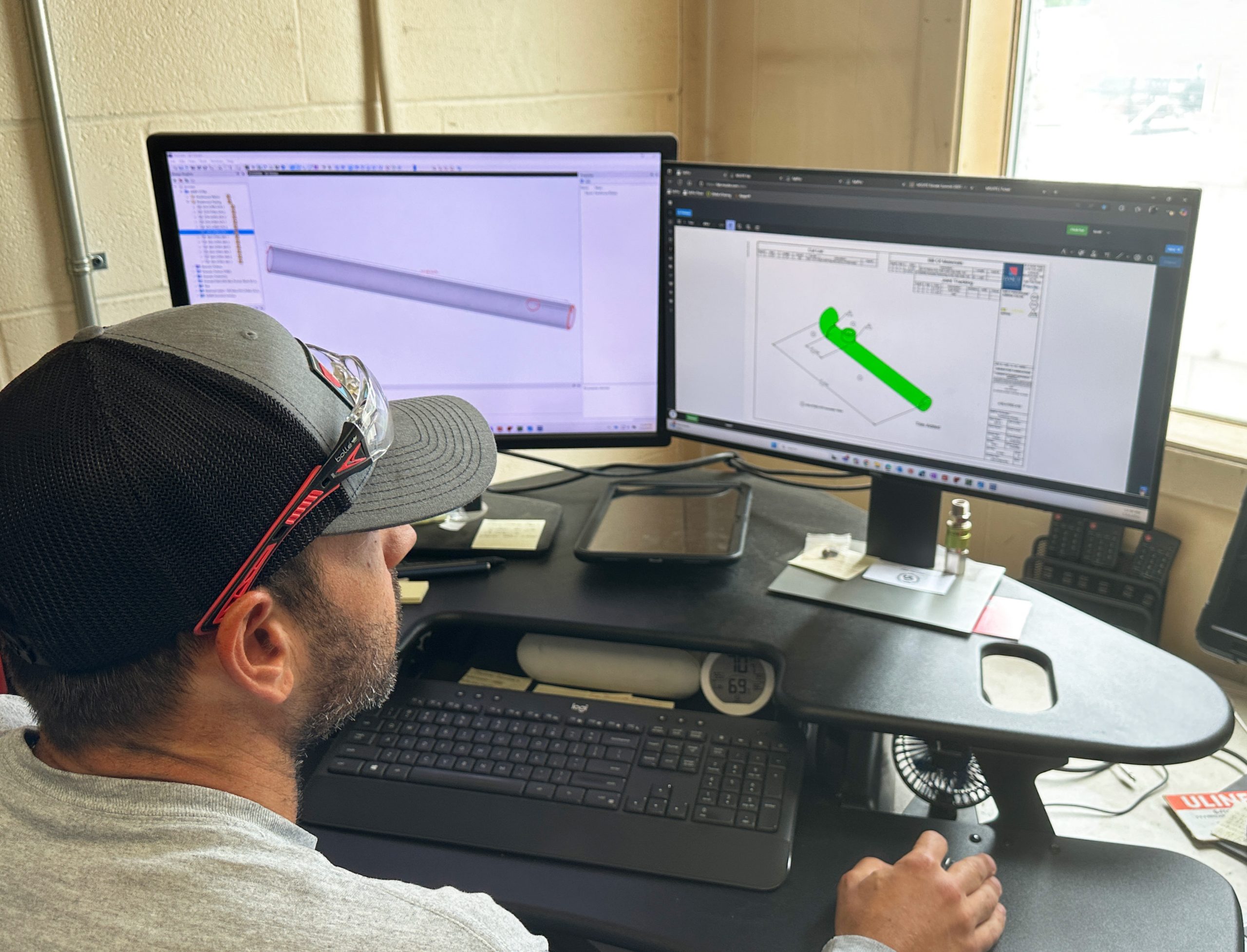

SOFTWARE SYNERGY

MSUITE BIM, a plugin to design software (Revit) and SpoolFab, generates spool drawings that integrate seamlessly with MSUITE FAB and CNC cutting software. On the vessel side, SolidWorks models are exported to isometric spool drawing software SpoolFab, eliminating manual take-offs, and can be directly imported to fabrication tracking software MSUITE FAB.

“For our VDC team, the tools make the transition from design to spooling incredibly efficient. MSUITE BIM has given our shop and field associates a better product.”

TYLER PETERSON

VP of Manufacturing

Bassett Mechanical

IMPACT ON DOCUMENTATION

MSUITE has also transformed Bassett Mechanical’s approach to project documentation. By centralizing drawings, material lists, and change orders within a digital platform, the software ensures that everyone—from engineers to shop floor staff— works from the most current set of plans.

This has minimized confusion, reduced costly errors from outdated documents, and improved collaboration across departments. The enhanced transparency and traceability have streamlined audits and compliance reporting, saving time and increasing customer confidence.

“MSUITE has transformed how we manage the shop. We continue to push the boundaries of what’s possible in fabrication by leveraging MSUITE’s innovative technology.”

TYLER PETERSON

VP of Manufacturing

Bassett Mechanical

KEY RESULTS

Since adopting MSUITE solutions, Bassett Mechanical has achieved measurable improvements:

- — INCREASED EFFICIENCY: Real-time updates and streamlined workflows have led to faster fabrication timelines.

- — REDUCED ERRORS: Enhanced coordination between design and fabrication has minimized costly mistakes and rework.

- — ENHANCED VISIBILITY: Shop floor teams and project managers now have access to live data, enhancing decision making and overall productivity.