Design Automation for MEP Professionals

By leveraging the power of your industry experience and ours, MSUITE BIM’s rule-based automation allows users to quickly automate fabrication spool & sheet creation, hanger placement, point layout, shop drawings and more.

Spools and Sheets

Create Spools Once

Auto Spool rapidly creates assemblies using construction logic and project parameters to ensure that what gets fabricated in the shop will work for the field.

Less Time Detailing

DIY Spool Sheets easily automates the placement of views, dimensions, tags, and more. Whether you are placing dimensions on 3D views or Weld Mapping, let MSUITE BIM MEP automate it.

Hangers and Supports

Instant Hanger Placement and Reporting

Empower design teams by removing tedious hurdles like properly placing hangers throughout a model.

Easily Layout and Communicate Point Locations

Collaborate with layout teams in the field by automating point placement and reporting. Quickly create thousands of points and send them and the model straight to your total station equipment in the field.

Integrating BIM to Fab

Integrate with existing systems

Seamlessly push to/from MSUITE BIM to Autodesk BIM360 Docs and Forge for 2d and 3d.

Integrate with shop equipment

Connect model information directly to the cut tables.

MSUITE BIM PRODUCT FEATURES

The plug-in for Autodesk® Revit® provides an in-application ribbon containing tools to help expedite spool and sheet creation.

Automatically identify spools based on a set of rules.

Integration with MSUITE Fab, allowing enhancement of shop workflow and accurate transfer of information.

Manually create spools within seconds. Color spools as you go to quickly identify spools within the model.

Break preexisting spools quickly to adjust and make new spools.

Custom Titleblock support with Parameter mapping. Schedule Creation and Placement for cuts, joints and materials.

3-15 seconds to create a sheet, fully

annotated; another 15-60 seconds to

clean up manually. Average manual spooling = 5 – 10 min; MSUITE BIM Spooling = 30 seconds; 90 X FASTER.

Automatically dimension rolling offsets. Display Centers, Faces and Ends in any View – Plan, Elevation, or Isometric.

Automatic 80% Overlap-Free Tag and

Annotation Placement.

Construction Annotations with Dimensions, Item Number Tags, Size Tags, Continuation Tags and Dimensions to Grids.

MSUITE BIM updates are released every 2-3

weeks, and are heavily influenced by

customer feedback.

Export MAJs with item data from CAD,

Validate MAJ data in Revit, Fix Connections for imported items and Convert Spools.

Cloud Model Uploads to FabPro, so shopfloor can view 2D PDFs, spool map, and 3D model

3-15 seconds to create a sheet (depending on model size), fully annotated; another 15-60 seconds to clean up manually.

273 spools and sheets created in 15 minutes. 18 spools/minute. 11,000 spools created in a 70,000+ multi-trade Fabrication Part model created in 24 hours, running in background.

WHAT OUR CUSTOMERS ARE SAYING

PREDICTIVE ANALYTICS FOR YOUR SHOP

Increase visibility, productivity, and accuracy in your facility by leveraging MSUITE Fab to manage production as work moves from drawing approval through site receiving.

Enhance your process

Model Driven, PDFs, or Hand Drawn

Whether your work instructions come from BIM, CAD, PDF, or field drawing on a napkin, MSUITE Fab helps keep everything in one spot.

Automate

Fabrication estimates, timesheet reports, and process improvement feedback in real-time.

Easy to use

MSUITE Fab for the shop floor shows just the work needing to be done, in the order it needs to be done.

Optimize Production

Waste Reduction

With integrations into machines like TigerStop, RazorGauge, Watts, HGG, and PypeServer MSUITE is able to optimize your cutting processes.

Increase Productivity

Stay on track with the most advanced materials and labor progressing in the industry. MSUITE Fab automatically turns shop floor production data into actionable insights you can use to improve your efficiency and productivity.

Streamline Communication

Whether it is the endless emails asking when things will be shipped or the drawing changes on the fly, MSUITE Fab streamlines communications between office, shop, and field teams with real-time notification of things like approvals for fabrication, drawing markups, trucks leaving the shop, and more.

MSUITE empowers our design team to efficiently collaborate with fabrication and construction teams to produce drawings at an unprecedented rate.

JOHN TRAMMELL | DIRECTOR OF VDC TECHNOLOGIES AT THE BRANDT COMPANIES

MSUITE FAB PRODUCT FEATURES

Paperless shop floor, version control, 2D & 3D viewers. Upload from design software or drawings from the field.

Keep & share all markups documented with the most up-to-date drawing versions.

Push data directly from Autodesk Revit & Fabrication CADmep to MSUITE Fab.

Integrates the digital approval process in one system.

Feed cuts from Revit to MSUITE Fab to machine controllers while collecting productivity data.

Access MSUITE Fab anywhere, from any

device with Internet connection.

Control what can be done or seen in the

system by Tier level or down to a specific user.

Leveraging passive tracking for real-time earned value & project analytics. Accessible to the fabrication shop, field & VDC teams.

Automated employee shift & cost code tracking provides accurate data for daily time-sheets.

Sortable, filterable tables allow for unique data flexibility & customization.

Automatically generate multiple documents such as: Welder continuity log, BOL, Weld Tracking, & Labels.

Companies can define their own workflows & stages. Select visible data at each stage & create conditional workflows based on project specs.

Package & Spools can be assigned a priority level to instantly identify items on hold vs rush order items.

Manage your shipment requests & due dates between the shop & field. Automatic creation of BOL including collated drawings and weld log when loading the truck. Digital receiving stages.

WHAT OUR CUSTOMERS ARE SAYING

Increase Jobsite Productivity

Never lose sight of project statuses, materials, manpower and issues.

Track Fabrication in Real-Time

Logistics Management for the Field

Increase visibility, clarity, and communication between your Field and Shop teams by leveraging MSUITE to track the status of fabrication packages, create fabrication requests and receiving materials on site.

Your Priorities at Your Fingertips

MSUITE allows you to change your priorities as job site conditions change. Simply move your shipping request date or pause your work on the shop floor and the shop will be notified immediately of your changes.

Receive Materials On Site

Optional Signature Requirements

Validate that a shipment arrived and automate notifications to key personnel. MSUITE tracks what shipments arrived, when they arrived, and who signed for them so that you can be assured your fabrication arrived on time and at the proper location.

Inventory Received Items and Verify Quality

Seamlessly scan barcoded labels to check-in received items on site and automatically communicate the status of the shipped items and their condition.

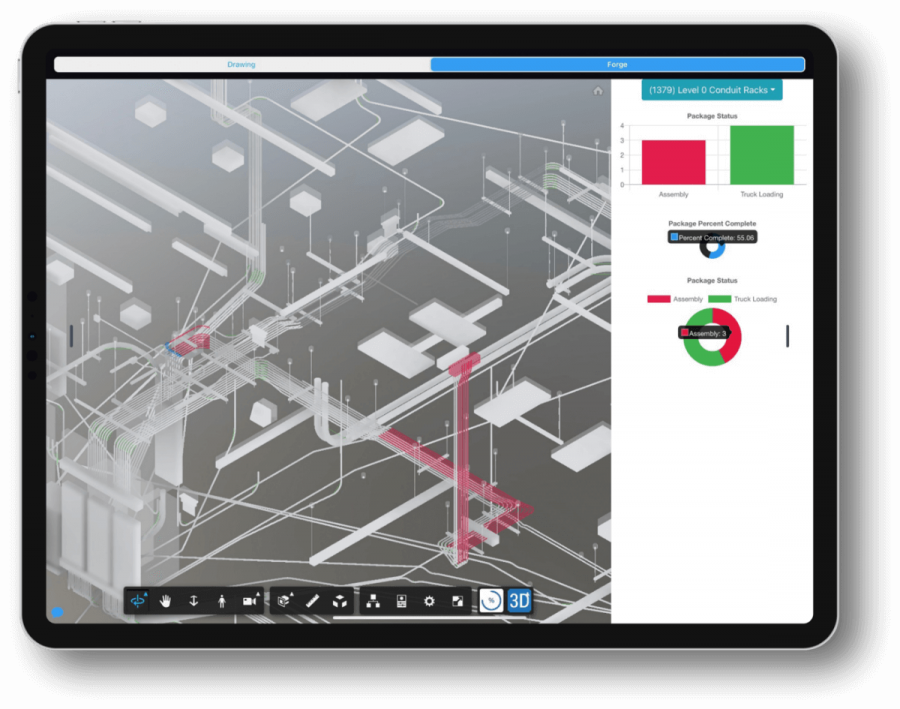

Integrating BIM to Field

Reach into the Model from the Field

Grab data like fabrication status to better visualize the schedule difference between plan vs. actual.

One Sheet of Music

By leveraging the integration with Autodesk BIM 360, MSUITE shows you the most up-to-date model data and drawings ensuring that everyone is working from the same information.

One of the most important factors to control cost and quality in the mechanical contracting industry is to enable multiple teams to work together in a seamless workflow. Having a second-to-none fabrication team work seamlessly with the Detailers and onsite construction crews makes MSUITE’s innovative technology unique and remarkable.

DAVID CONLEY | DIRECTOR OF MANUFACTURING AT LEE COMPANY

WHAT OUR CUSTOMERS ARE SAYING

Innovating Sheet Metal Fabrication Shops

Sheet metal fabrication is a combination of science and art. There are numerous processes and nuanced techniques which make it essential to have a skilled fabrication team and running a high performing fabrication shop. MSUITE is revolutionizing the fabrication shop for sheet metal contractors across North America.

Enhance your process

Model Driven, PDFs, or Hand Drawn

Whether your work instructions come from BIM, CAD, PDF, or field drawing on a napkin, MSUITE FAB helps keep everything in one spot.

Automate

Fabrication estimates, timesheet reports, and process improvement feedback in real-time.

Easy to use

MSUITE FAB for the shop floor shows just the work needing to be done, in the order it needs to be done.

Optimize Production

Waste Reduction

With integrations into machines like TigerStop, RazorGauge, Watts, HGG, and PypeServer, MSUITE FAB is able to optimize your cutting processes.

Increase Productivity

Stay on track with the most advanced materials and labor progressing in the industry. MSUITE FAB automatically turns shop floor production data into actionable insights you can use to improve your efficiency and productivity.

Streamline Communication

Whether it is the endless emails asking when things will be shipped or the drawing changes on the fly, MSUITE FAB streamlines communications between office, shop, and field teams with real-time notification of things like approvals for fabrication, drawing markups, trucks leaving the shop, and more.

We love MSUITE and the BIM 360 Integration. Being able to see spools in 3D and 2D saves a great deal of time, eliminating questions from the shop.

BRADY COULOMBE | MANAGER, PETERSON SHEET METAL

PRODUCT FEATURES FOR SHEET METAL FAB SHOPS

Paperless shop floor, version control, 2D & 3D viewers. Upload from design software or drawings from the field.

Keep & share all markups documented

with the most up-to-date drawing versions.

Push data directly from Autodesk Revit & Fabrication CADmep to MSUITE FAB.

Integrates the digital approval process in one system.

Feed cuts from Revit to MSUITE FAB to machine controllers while collecting productivity data.

Access MSUITE FAB anywhere, from any

device with Internet connection.

Control what can be done or seen in the

system by Tier level or down to a specific user.

Leveraging passive tracking for real-time earned value & project analytics. Accessible to the fabrication shop, field & VDC teams.

Automated employee shift & cost code tracking provides accurate data for daily time-sheets.

Sortable, filterable tables allow for unique data flexibility & customization.

Automatically generate multiple documents such as: Welder continuity log, BOL, Weld Tracking, & Labels.

Companies can define their own workflows & stages. Select visible data at each stage & create conditional workflows based on project specs.

Package & Spools can be assigned a priority level to instantly identify items on hold vs rush order items.

Manage your shipment requests & due dates between the shop & field. Automatic creation of BOL including collated drawings and weld log when loading the truck. Digital receiving stages.

Fabrication Shop Innovation

Fabrication is a combination of science and art. There are numerous processes and nuanced techniques which make it essential to have a skilled fabrication team and running a high performing fabrication shop. MSUITE is revolutionizing the fabrication shop for Mechanical, Plumbing, and Piping Contractors across North America.

Enhance your process

Model Driven, PDFs, or Hand Drawn

Whether your work instructions come from BIM, CAD, PDF, or field drawing on a napkin, MSUITE FAB helps keep everything in one spot.

Automate

Fabrication estimates, timesheet reports, and process improvement feedback in real-time.

Easy to use

MSUITE FAB for the shop floor shows just the work needing to be done, in the order it needs to be done.

Optimize Production

Waste Reduction

With integrations into machines like TigerStop, RazorGauge, Watts, HGG, and PypeServer, MSUITE is able to optimize your cutting processes.

Increase Productivity

Stay on track with the most advanced materials and labor progressing in the industry. MSUITE automatically turns shop floor production data into actionable insights you can use to improve your efficiency and productivity.

Streamline Communication

Whether it is the endless emails asking when things will be shipped or the drawing changes on the fly, MSUITE FAB streamlines communications between office, shop, and field teams with real-time notification of things like approvals for fabrication, drawing markups, trucks leaving the shop, and more.

The integration between MSUITE BIM to MSUITE FAB to TigerStop helps Gallo Mechanical save money, increase productivity and efficiency, and reduce risks in the shop.

RAY MCDONALD | GENERAL MANAGER AND FABRICATION COORDINATOR

PRODUCT FEATURES FOR MECHANICAL, PLUMBING, AND PIPING CONTRACTORS

Paperless shop floor, version control, 2D & 3D viewers. Upload from design software or drawings from the field.

Keep & share all markups documented with the most up-to-date drawing versions.

Push data directly from Autodesk Revit & Fabrication CADmep to MSUITE FAB.

Integrates the digital approval process in one system.

Feed cuts from Revit to MSUITE FAB to machine controllers while collecting productivity data.

Access MSUITE FAB anywhere, from any device with Internet connection.

Control what can be done or seen in the system by Tier level or down to a specific user.

Leveraging passive tracking for real-time earned value & project analytics. Accessible to the fabrication shop, field & VDC teams.

Automated employee shift & cost code tracking provides accurate data for daily time-sheets.

Sortable, filterable tables allow for unique data flexibility & customization.

Automatically generate multiple documents such as: Welder continuity log, BOL, Weld Tracking, & Labels.

Companies can define their own workflows & stages. Select visible data at each stage & create conditional workflows based on project specs.

Package & Spools can be assigned a priority level to instantly identify items on hold vs rush order items.

Manage your shipment requests & due dates between the shop & field. Automatic creation of BOL including collated drawings and weld log when loading the truck. Digital receiving stages.

Innovating Electrical Fabrication Shops

Electrical fabrication is a combination of science and art. There are numerous processes and nuanced techniques which make it essential to have a skilled fabrication team and running a high performing fabrication shop. MSUITE is revolutionizing the fabrication shop for Electrical Contractors across North America.

Enhance your process

Model Driven, PDFs, or Hand Drawn

Whether your work instructions come from BIM, CAD, PDF, or field drawing on a napkin, MSUITE FAB helps keep everything in one spot.

Automate

Fabrication estimates, timesheet reports, and process improvement feedback in real-time.

Easy to use

MSUITE Fab for the shop floor shows just the work needing to be done, in the order it needs to be done.

Optimize Production

Waste Reduction

With integrations into machines like TigerStop, RazorGauge, Watts, HGG, and PypeServer, MSUITE FAB is able to optimize your cutting processes.

Increase Productivity

Stay on track with the most advanced materials and labor progressing in the industry. MSUITE FAB automatically turns shop floor production data into actionable insights you can use to improve your efficiency and productivity.

Streamline Communication

Whether it is the endless emails asking when things will be shipped or the drawing changes on the fly, MSUITE FAB streamlines communications between office, shop, and field teams with real-time notification of things like approvals for fabrication, drawing markups, trucks leaving the shop, and more.

At Shapiro & Duncan, we are pushing the envelope to increase productivity, reduce costs, and increase communications. MSUITE allows our staff to manage prefabrication operations at a distance and build efficiently.

CHRIS CANTER | DIRECTOR OF VIRTUAL DESIGN AND FABRICATION

PRODUCT FEATURES FOR ELECTRICAL CONTRACTORS

Paperless shop floor, version control, 2D & 3D viewers. Upload from design software or drawings from the field.

Keep & share all markups documented with the most up-to-date drawing versions.

Push data directly from Autodesk Revit & Fabrication CADmep to MSUITE FAB.

Integrates the digital approval process in one system.

Feed cuts from Revit to MSUITE FAB to machine controllers while collecting productivity data.

Access MSUITE FAB anywhere, from any

device with Internet connection.

Control what can be done or seen in the

system by Tier level or down to a specific user.

Leveraging passive tracking for real-time earned value & project analytics. Accessible to the fabrication shop, field & VDC teams.

Automated employee shift & cost code tracking provides accurate data for daily time-sheets.

Sortable, filterable tables allow for unique data flexibility & customization.

Automatically generate multiple documents such as: Welder continuity log, BOL, Weld Tracking, & Labels.

electrical contractors can define their own workflows & stages. Select visible data at each stage & create conditional workflows based on project specs.

Package & Spools can be assigned a priority level to instantly identify items on hold vs rush order items.

Manage your shipment requests & due dates between the shop & field. Automatic creation of BOL including collated drawings and weld log when loading the truck. Digital receiving stages.

PREDICTIVE ANALYTICS FOR YOUR SHOP

Increase visibility, productivity, and accuracy in your facility by leveraging MSUITE FAB to manage production as work moves from drawing approval through site receiving.

Optimize Shop Floors

Reduced Risk – Automatic version control and removing drawings on shop floor when placing on hold.

Weld Log Automation – Get 100% traceability to any weld and quality results to reduce overhead costs by digitizing your documentation process.

Automated time sheets enables Fabricators to maximize profitability and better manage labor costs for jobs, packages, and bays.

Shop Benefits

Status Tracking

Automated real-time status tracking of job, package, iso, or spools from concept to completion keeps the PM, Engineer, and Fab Shop Manager on the same page.

Leverage your data

MSUITE automatically turns shop floor production and quality control data into actionable insights to improve efficiency and productivity.

Post-Weld Logistics

Your one-stop shop for automatic routing of post-weld processes (e.g., X-Ray, Paint, Coatings, Hydro Testing, etc.).

Configurable Workflows

Structure & streamline workflows to connect, automate and optimize work processes between engineering, project, and fabrication teams.

JIM TEDROW | MSUITE HELPS PRIORITIZE THE WORK FOR OUR SHOP MANAGERS TO MAKE SURE WE’RE ON THE RIGHT TRACK.

PRODUCT FEATURES FOR INDUSTRIAL FABRICATORS

Improve the integrity and accuracy of your QA & QC program by digitally tracking your Nondestructive Evaluations (NDE).

Create and capture all markups documented

with the drawings to handover.

Gain control in all processes – digitally capturing welder ID, welding procedures, heat numbers, inspector, QA process, QA results for reporting and administration.

Integrates the digital approval process in one system. Verify drawing accuracy, BOM, cuts, joints & fabrication readiness.

Automate routing of post-weld processes (e.g., X-Ray, Paint, Coatings, Hydro Testing, etc.).

Securely access MSUITE FAB anywhere, from any device. Custom role and user-based permissions control access to the data.

Improve the handover experience from engineering and detailing to fabrication.

Get notifications of backorders and missing items; Track heat numbers, automated status log, and leverage passive tracking for real-time earned value & project analytics.

Automated shift & cost code tracking provides accurate data for daily time-sheets.

Sortable, filterable tables allow for unique data flexibility & customization. Leverage reports and custom dashboards.

Automatically generate multiple documents such as: Drawing Status Report, Weld Tracking, BOL, & Final Drawing Markups.

Companies can define their own workflows & stages. Select visible data at each stage & create conditional workflows to follow project specs.

Drawings & Spool priority can be managed from anywhere instantly identifying rush order drawings vs. drawings on hold.

Manage your shipment requests & due dates. Automatic creation of BOL including collated drawings and weld log when loading the truck. Digital receiving stages.

Timecard Automation for the Fab Shop

Timecard automation for the Fab Shop saves time, improves timesheet accuracy, eliminates double entry, and boosts employee productivity.

SAVES TIME

Eliminate the manual effort and hours spent on time entry, timecard submission, review, and analysis. By passively automating time tracking the data capturing and approval process becomes much more seamless. Download PDF >

IMPROVES TIMECARD ACCURACY

Automated timecards provide a more detailed and accurate account of tasks, cost codes and activities as there is no room for human error. This gives you better insight into how you and your team members utilize time, allowing you to spot inefficiencies, letting you know which work is most profitable.

BOOSTS EMPLOYEE PRODUCTIVITY

MSUITE’s time tracking shows each employee’s total time on their tasks and cost code. This allows you to understand time use better and distribute workload according to their expected output. MSUITE also provides essential project performance data to identify potential bottlenecks in your shop.

ELIMINATES DOUBLE ENTRY

MSUITE allows you to export timecard data in a format that easily imports to your Accounting/ERP system. This saves your team time and eliminates human error that comes with double entry.

We love MSUITE and the BIM 360 Integration. Being able to see spools in 3D and 2D saves a great deal of time, eliminating questions from the shop.

MSUITE BIM is crucial to helping Brandt deliver superior designs and accurate fabrication to commercial and industrial facilities across Texas.

JOHN TRAMMELL | DIRECTOR OF VDC