Dodge Data Report & Analytics, a leading researcher for the construction industry, recently released the Prefabrication and Modular Construction 2020 SmartMarket Report. Their latest research reveals that Mechanical, Electrical and Plumbing (MEP) contractors around the U.S. are seeing extraordinary value from the use of BIM and prefabrication.

The Dodge report provides a comprehensive examination of the current state and future expectations for prefabrication and modular construction. It focuses on the architects, engineers, and MEP contractors using prefabrication and permanent modular construction methods to understand better the benefits and key drivers of use and pitfalls.

Commercial Construction Benefits & Adoption

The benefits of using model-based prefabrication are striking with an average of 90% of users reporting improved quality, increased schedule certainty and productivity using these methods compared to traditional stick-built construction methods. In addition, at least 80% of users reported reduced waste, increased customer satisfaction and improved cost predictability.

As the MEP & Modular construction industry recognizes the incredible cost savings of integrating prefabrication into commercial construction, at the core is enabling teams to track, manage and collaborate using lean manufacturing and fabrication best practices and powerful, innovative technology to improve performance.

The competition is heating up with the drive to adopt prefab and modular construction. With an industry-wide labor shortage and other circumstances beyond our control – everything from weather to supply-chain issues – it is simply not efficient or economical to stick-build everything and delaying adoption will ensure MEP contractors eventually fall behind.

Adopting prefabrication in commercial construction projects is crucial for several compelling reasons:

- Prefabrication offers significant time savings compared to traditional construction methods, as components can be manufactured off-site concurrently with on-site preparations. This simultaneous process accelerates project timelines, reducing overall construction durations and enabling faster occupancy or utilization of the commercial space.

- Prefabrication enhances cost efficiency by minimizing on-site labor requirements and optimizing material usage. The controlled environment of off-site manufacturing also ensures higher precision and quality in the fabrication of building components, resulting in reduced errors and rework.

- Prefabrication aligns with sustainability goals, as it often involves using recycled materials and promotes resource efficiency.

By embracing prefabrication, the commercial construction firms can enhance productivity, control costs, and develop more resilient and sustainable structures in an increasingly demanding and competitive market.

Key Learnings in Dodge Data Report:

- Percentage of Mechanical Pre-Assemblies

- Material Waste

- Labor Cost

- Quality Work of Installed

- Worker Safety

- Site Logistics Cost

The Dodge Data Report also provides details of the current state and future expectations for prefabrication and modular construction. The benefits of use indicated in the Dodge Report are eye popping for general contractors, trade contractors, and construction professionals. Below are many of the findings:

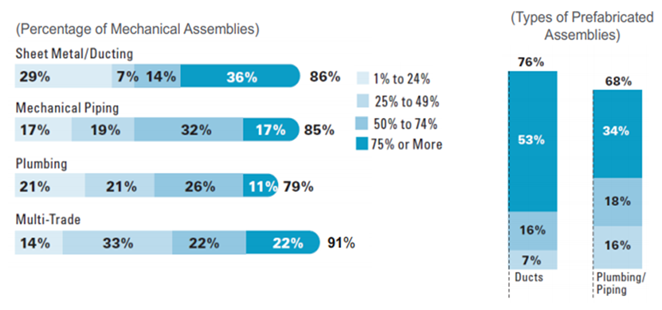

Dodge Data Reports: Participant Trades, Percentage of Usage and Types of Prefabricated Assemblies

- 86% Sheet Metal/Ducting (36% reported a 75% or More impact improvement)

- 85% Mechanical Piping (17% reported a 75% or More impact improvement)

- 79% Plumbing (11% reported a 75% or More impact improvement)

- 91% Multi-Trade (22% reported a 75% or More impact improvement)

The below section presents significant impact improvements for trade contractors using model-based prefabrication in select categories, including Material Waste, Labor Cost, Quality of Installed Work, Worker Safety, Site Logistics Cost, Avoiding Unplanned Purchases, and Schedule Performance. All categories studied by Dodge Data & Analytics indicated substantial improvements using Model-Based Prefabrication.

Dodge Data Reports: Impact Improvements of Model-Based Prefabrication

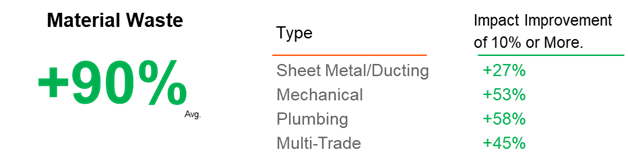

- An average of 90% report major improvement on material waste compared to traditional stick-built construction.

- Waste reduction on the job site includes cost savings and safety.

- Reduced debris = reduced trip hazards on a job site.

- Owners also appeal to construction sites that are cleaner than expected.

- An average of 88% report decreased labor costs. A top driver for increased use of prefab and modular construction.

- Sheet Metal/Ducting and Plumbing report the highest impact improvement among Mechanical and Multi-trade assembly types.

- An average of 86% indicate the Quality of Work improved.

- Manufacturing empowers expanded training opps and quality control.

- Automated equipment and mitigating weather issues leads to improved productivity and quality of work at the jobsite.

Advanced work conducted in the controlled manufacturing environment eliminates many time-draining issues of frequently running out of materials on the job site. Supply chain issues, RFI responses, and labor schedules are all streamlined to avoid delays. Adopting lean manufacturing and prefabrication best practices significantly increases the quality of work, as well.

- An average of 79% report Worker Safety improved across all trades.

- Reduces fatigue, potential for accidents and optimizes worker scheduling.

- Fab Shops offer controlled and safe environments.

Dodge Data Reports: BIM optimizes the prefabrication and modular construction workflow

Construction market trends such as high costs, lower profit margins, shorter project schedules and labor shortages are a few of the reasons why MEP construction firms plan to increase their adoption and use of prefabrication and modular building. Other studies demonstrate companies can increase production 3 times by adopting the methodology.

- An average of 71% report Site Logistics Cost improvement.

- Pre-planning with BIM and prefabricated models helps control costs.

- Reduces costly rework on the jobsite where changes create costly delays.

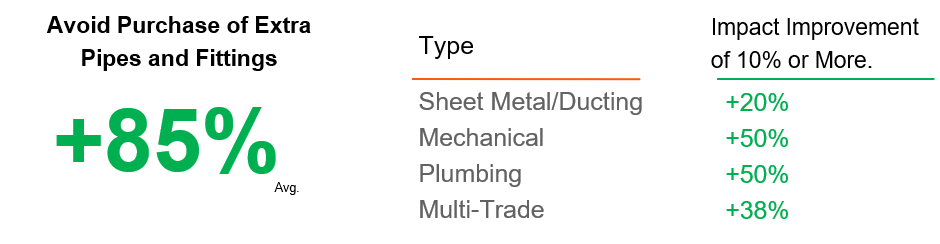

- An average of 85% credit Model-Based Prefabrication with avoiding the need to purchase extra pipes and fittings on the jobsite.

- BIM improves the accuracy of prefabrication and modular processes.

- Mechanical contractors indicate a substantial 50% impact improvement.

- An average of 84% indicate improved schedule performance.

- Increased schedule certainty – control, materials, and labor on the jobsite.

- The impact of poor weather is mitigated with fabrication offsite.

Charting a new course in the construction industry

Dodge Data’s research clearly demonstrates that prefabrication and modular construction are providing significant improvements and efficiencies for construction firms. The question for MEP Contractors is how to move diligently and leverage best practices and the right technology to connect BIM to FAB to Field teams, so they work in a singular workflow. It’s not a surprise that more MEP Contractors plan to use model-based prefabrication and modular construction to increase their competitive positions.

MEP Construction firms need to push the envelope to increase productivity, reduce costs, and improve communications. Many construction market factors, including chronic cost and schedule overruns and the lack of adequate housing, and a shortage of skilled construction labor, are significant drivers towards fixing the broken workflows for construction builds.